In 2017 Cimar Electronics asked us to create a Visual Inspector that could verify if PCB’s are manufactured correctly. Doing this by hand takes a lot of time, and if a human is staring at the same PCB’s all day he or she can easily miss things. To further increase the quality of the produced products we created software that could grab an image using different kind’s of input, compare it with a reference image and find anomalies.

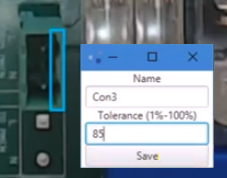

Defining PCB’s

Users can define PCB’s by scanning in a reference PCB. To limit the size of the pictures that need to be compared the sizes of the PCB need to be specified. PCB’s can consist of multiple components and because some components might vary more than others, a tolerance can be specified per component.

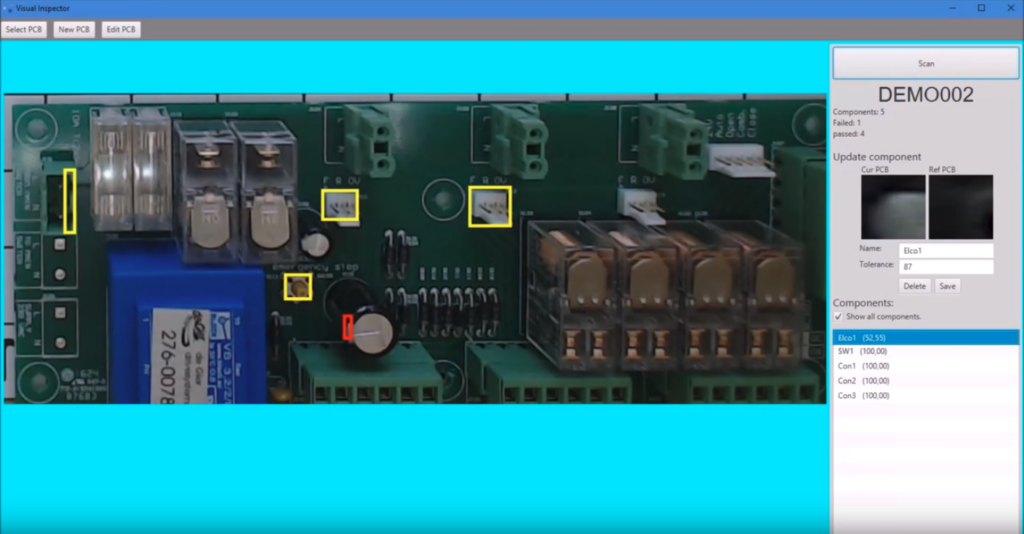

Inspection

When inspecting a PCB the system checks each component and compares it with the component on the reference PCB. If an anomalies are found the system will show the user which components are rejected and why. Users can always modify the component/PCB settings if needed.